Bottle Inspection System

Advanced bottle inspection systems with an outstanding inspection performance

Download the Brochure

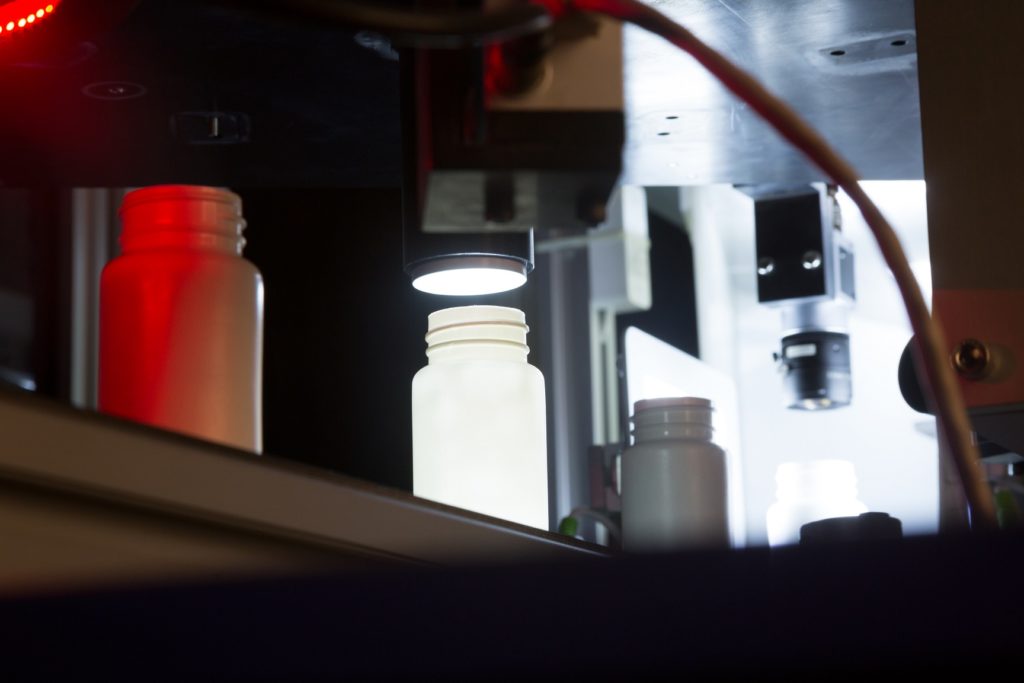

HIGH-END BOTTLE INSPECTION SYSTEM WITH AN OUTSTANDING INSPECTION PERFORMANCE

- Bottle Inspection Systems are crucial during the manufacturing process, as a number of defects can arise due to unavoidable conditions such as temperature variations, raw material defects, and contamination.

- Customers today are more demanding and have zero tolerance for defective products, making it essential for bottle manufacturing companies to inspect 100% of their products. Traditional methods of manual checking and sorting are no longer feasible.

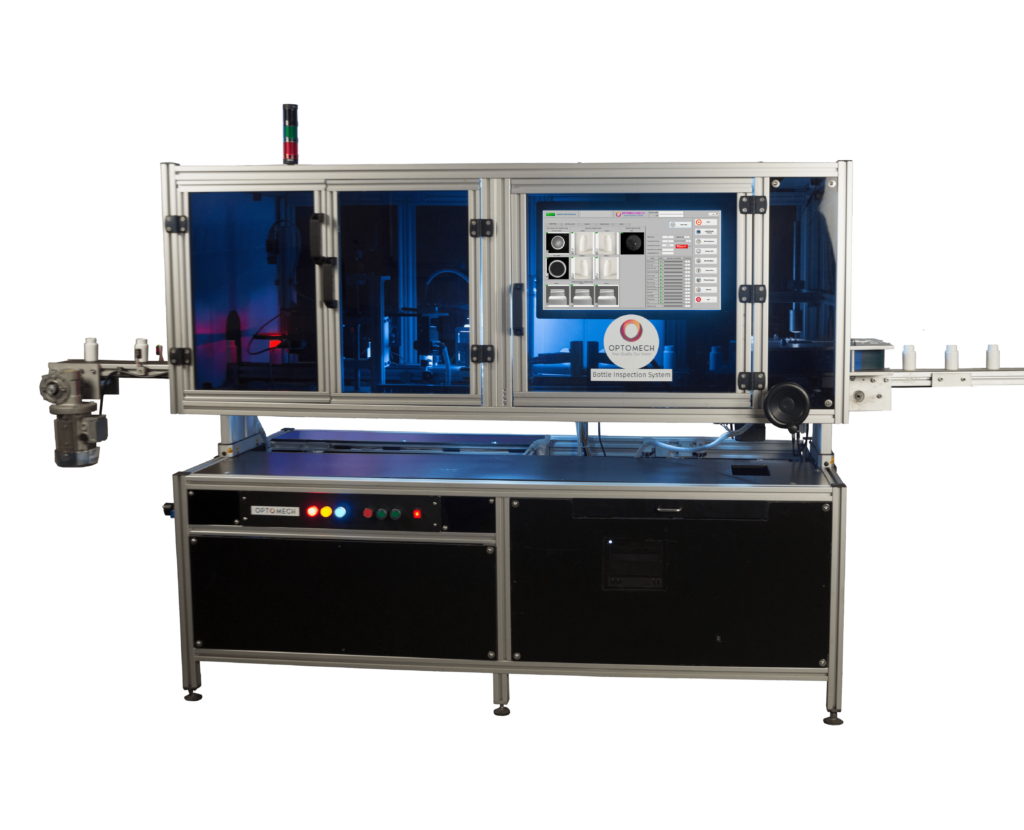

- The BIS-XL is a high-performance system that performs 100% inspection and sorting of bottles for all possible defects automatically, ensuring peace of mind for manufacturers and their customers. Optomech Engineers is an established manufacturer of a wide range of products, including Bottle Inspection Systems, Closure Inspection Systems, Label Inspection Systems, and Induction Sealing Integrity Verification Systems.

- Founded in Hyderabad, India, in 1981, Optomech has over 37 years of experience in the successful development, manufacturing, servicing, and marketing of products involving vision technology for quality inspection.

- We are closely oriented towards the needs of the market and are one of the leading providers of vision technologies for quality inspection. Renowned companies place their trust in the solutions and services provided by Optomech.

Salient Features

Better Speed, Security and Accuracy

High speed, machine vision cameras, precision optics and customised lighting coupled with state of the art 21 CFR Part 11 compliant software provide security, accuracy and repeatability.

Each bottle is inspected for multiple defects

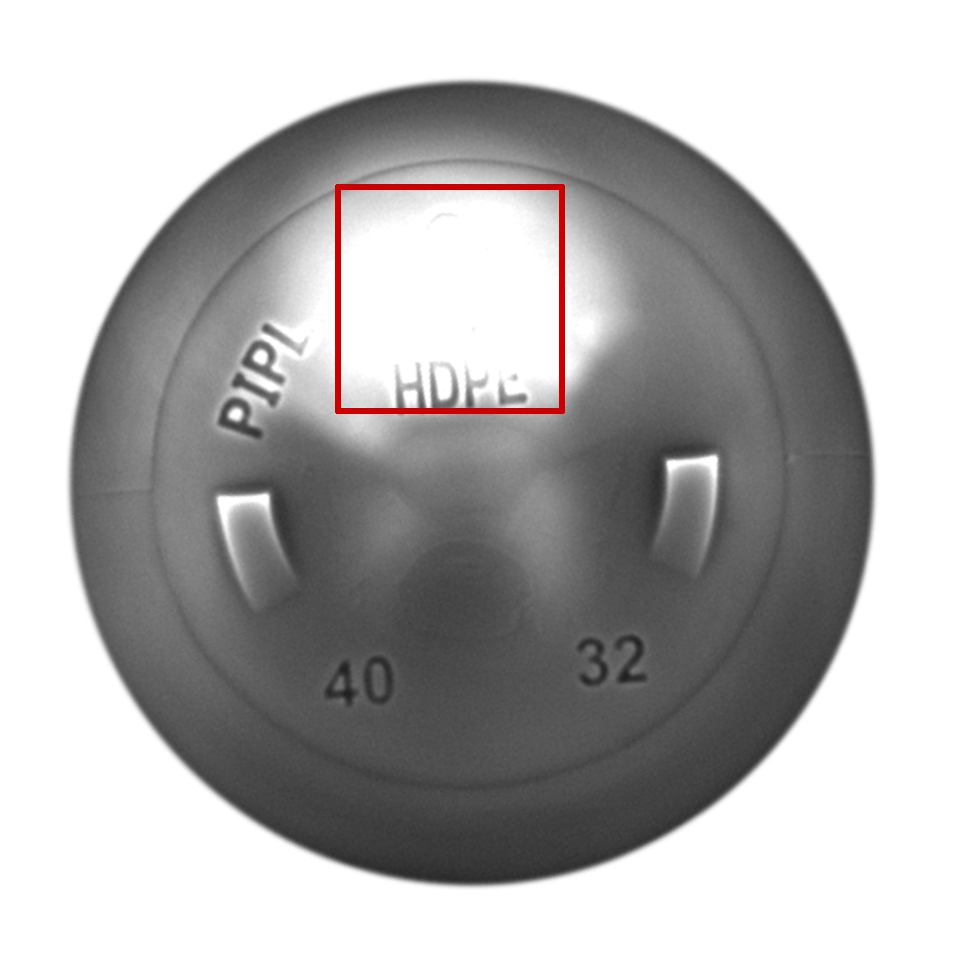

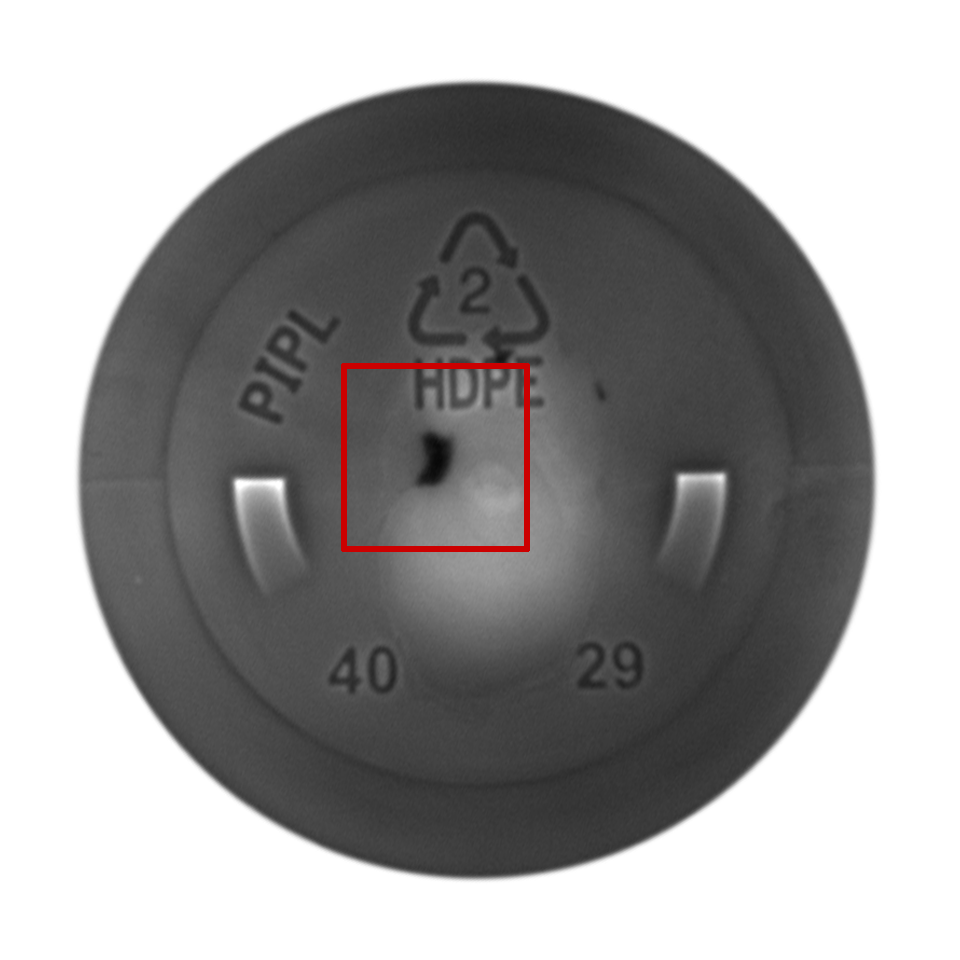

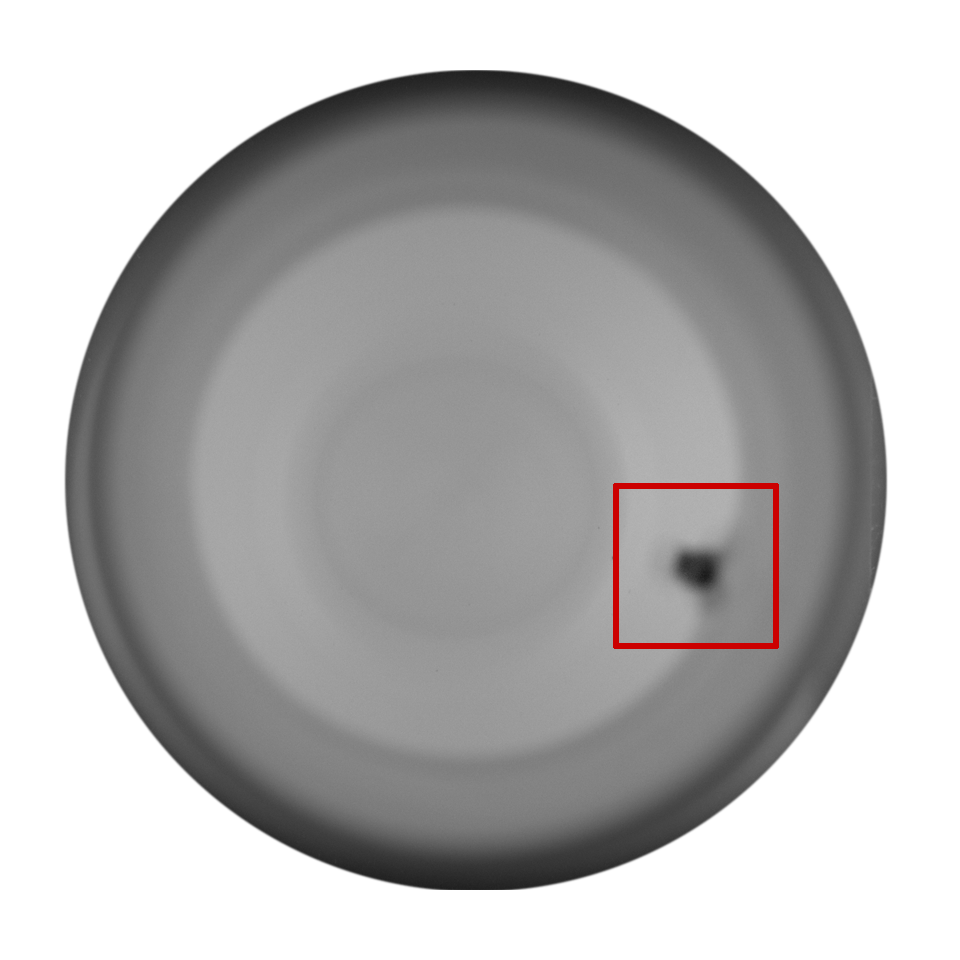

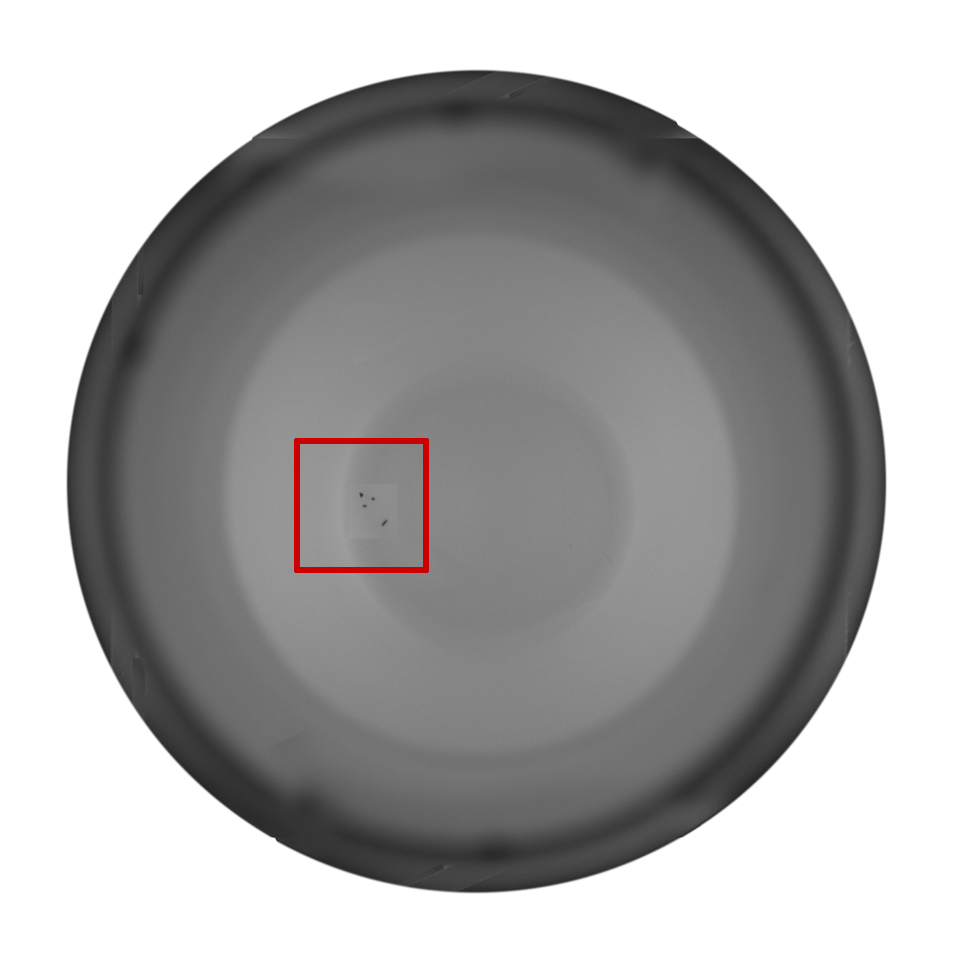

Each bottle is inspected for defects like spots, material inclusions, color smears, color shade variations, flashes, ovality, diameter variations, holes and transparency.

System Changeover for Faster Inspection

System changes over quickly to inspect new products. Changeover involves simply selecting the required product from the system library using the touch screen.

Role-based 3 Level Access

3 Level access control for ‘User’, ‘Supervisor’ and ‘Administrator’ through separate passwords.

Easy to Define Tolerances Level

Easy to define tolerances allow the user to decide which bottles need to be accepted or rejected.

Full Visual Defect Detection

Large monitor displays the image of the bottles as they are passing through the system.

HARDWARE FOR ADVANCED BOTTLE INSPECTION SYSTEMS

-

- Vision system consists of a number of high speed machine vision

cameras, high resolution optics and custom designed

lighting.

- Vision system consists of a number of high speed machine vision

-

- Bottles are transported through the system with the help of

two conveyors.

- Bottles are transported through the system with the help of

-

- Ergonomically designed enclosure with alarm and door

interlocks to prevent accidental opening during process.

- Ergonomically designed enclosure with alarm and door

-

- Data processing unit with 21“ touch screen monitor.

-

- Pneumatic ejection mechanism to eject the rejected

bottles.

- Pneumatic ejection mechanism to eject the rejected

PROCESS FOR ADVANCED BOTTLE INSPECTION SYSTEMS

-

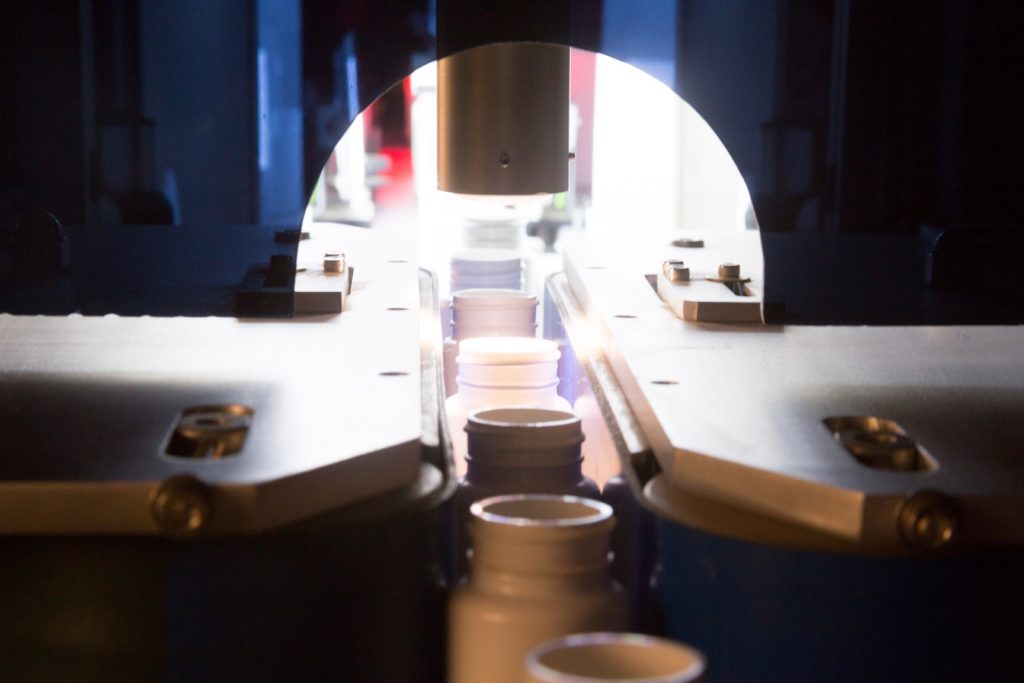

- Bottles are picked-up from the blow molding

machine’s conveyor by a clamp conveyor provided

in the Bottle Inspection Systems.

- Bottles are picked-up from the blow molding

-

- From the clamp conveyor the bottles are transferred

to the flat belt conveyor.

- From the clamp conveyor the bottles are transferred

-

- As the bottles pass through the system the high

speed camera capture images of the bottles from all

directions, the images are processed in realtime to

detect the defective bottles.

- As the bottles pass through the system the high

-

- Defective bottles are ejected from the system with

the help of the pneumatic ejection mechanism.

- Defective bottles are ejected from the system with

INSPECTION FOR ADVANCED BOTTLE INSPECTION SYSTEMS

-

- Large monitor displays the images of the bottles as they

are passing through the system.

- Large monitor displays the images of the bottles as they

-

- Results of the last 100 bottles are displayed onscreen.

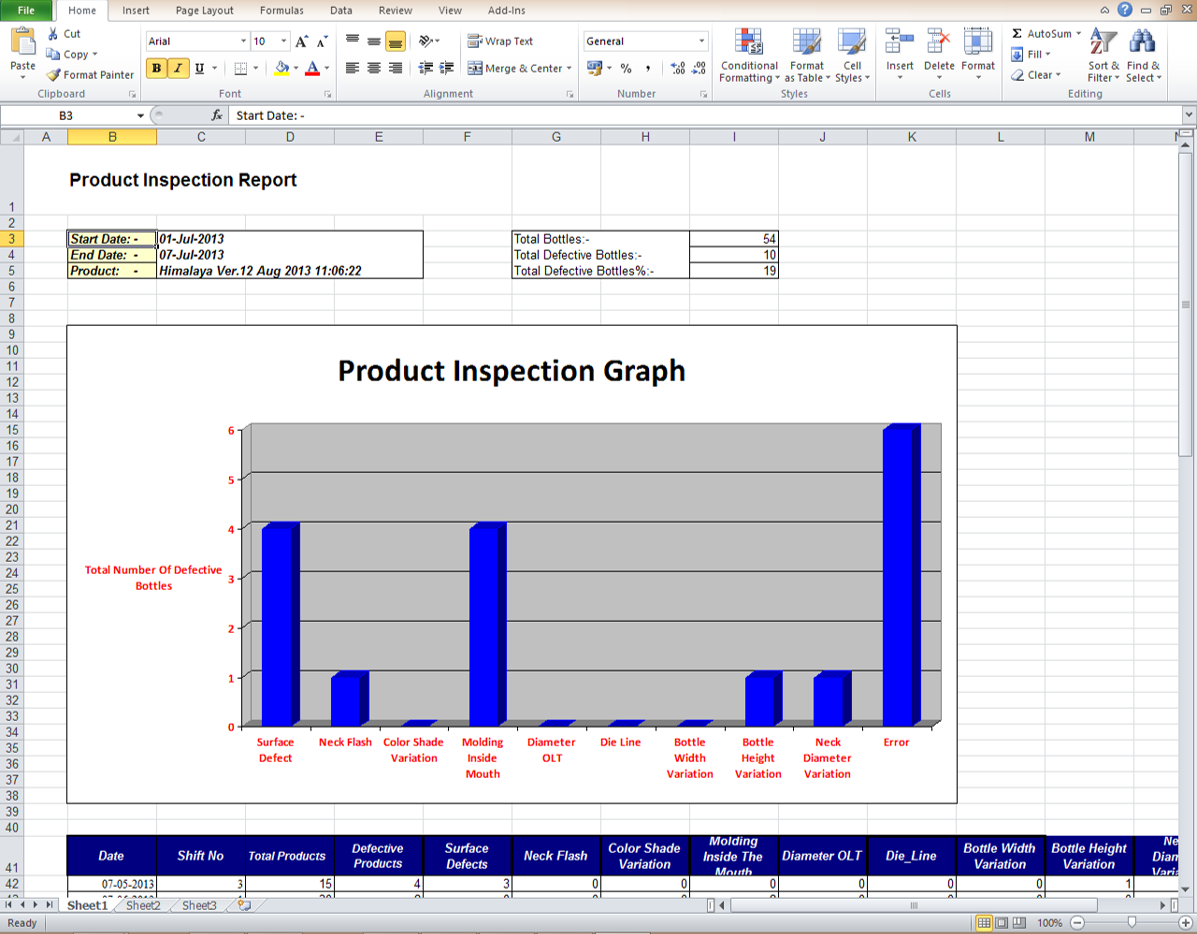

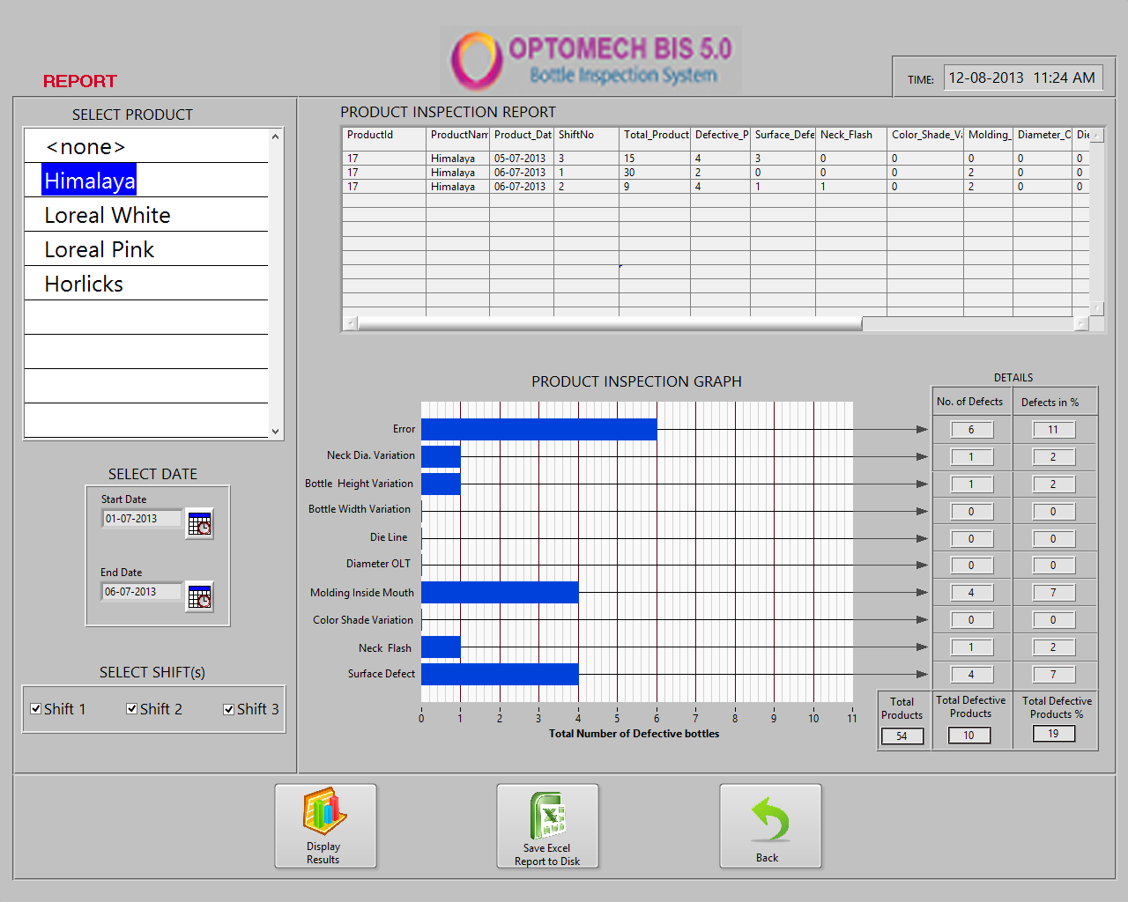

INSPECTION RESULTS

Inspection results are stored in the data base product wise

Detailed statistical reports can be generated and viewed in excel

Reporting

Result

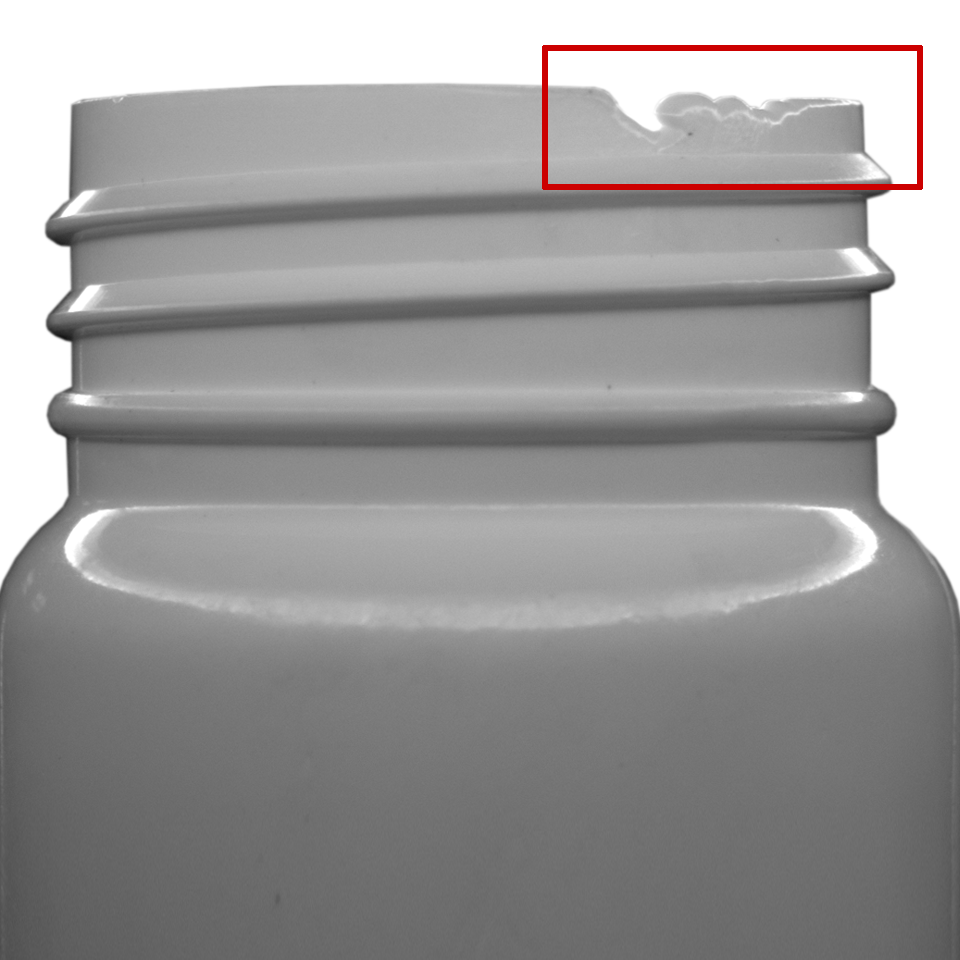

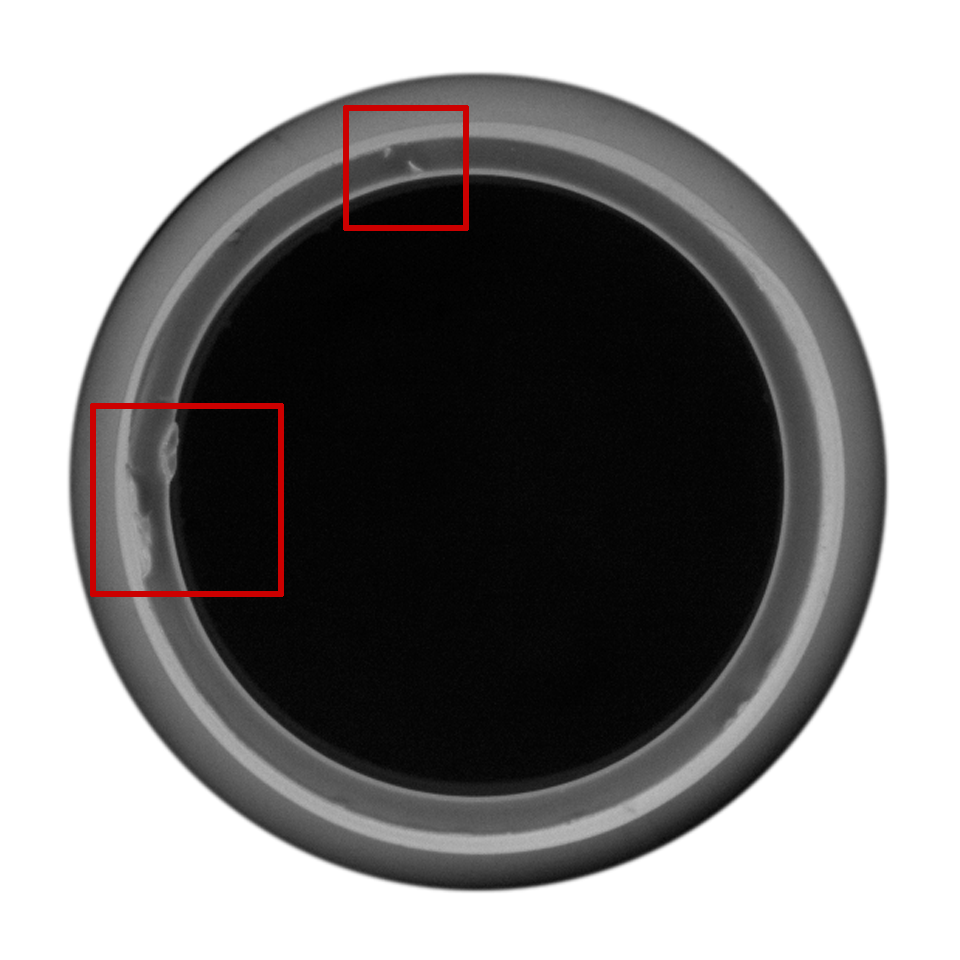

Typical Defects

- Bottle shape variation

- Incomplete blowing

- Color Shade Variation

- Black spots

- Flashes, Extra material

- Under/Short moulding

- Contamination

- Burn spots

- Coving .

- Short molding

- Extra material

- Ovality

- Diameter variation

- Transparency

- Ovality

- Holes

- Thin wall

- Pin Hole

- Incomplete blowing

- Black spots

- Thread Damage

- Contamination

- Black spots

- Incomplete blowing

- Dark spots

- Mateial Insert

High performance Bottle Inspection Machine

High-resolution inspection for complex bottle geometries, shapes, colors and material as well as transparent, opaque, shiny or matte bottles

Trusted by the thousands of companies

High performance online system for checking the visual defects in plastic bottles.

Need Help ? Get In Touch

Optomech’s Multiple camera advanced software allows the complete bottle to be inspected while virtually eliminating false rejects. provide all round inspection of top sealing surface.

Our Location

3A, Type II, I. E., Kukatpally,

Prashanti Nagar, Hyderabad

Let’s Talk

Phone: +91 903 2364 140,

+91 630 4432 763

Drop A Line

sales@optomech.in

Working Hours

Mon-Sat: 9:00AM – 5:30PM