Desiccant Canister Inspection System

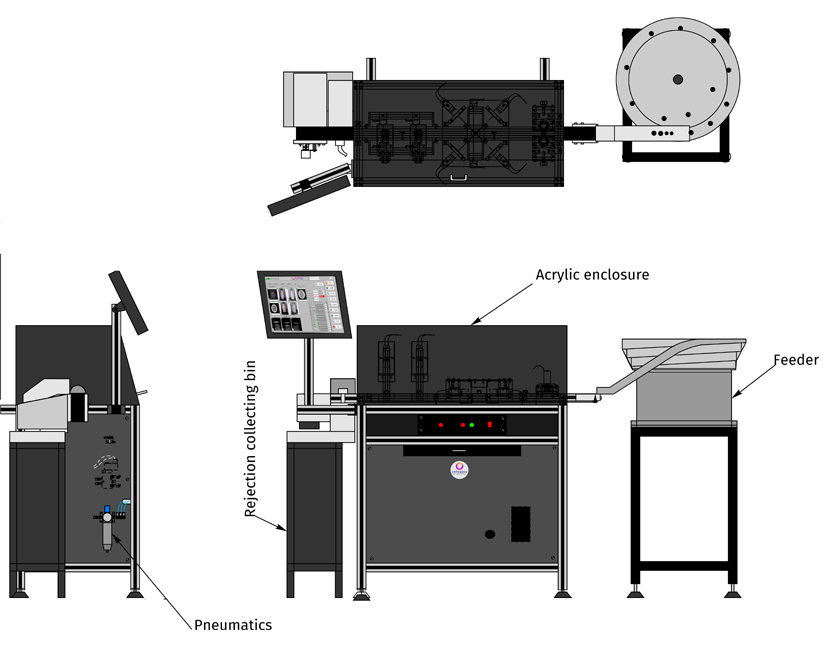

Optomech Desiccant Canister Inspection System (CANIS) is a high speed fully automatic inspection system for the all-round inspection of Silica gel canisters.

Canisters are inspected at the speed of 300 cans/caps per minute.

The stand alone machine consisting of feeder, conveyor, cameras and control systems, and ejection unit.

The complete machine is in caused in an ergonomically designed enclosure.

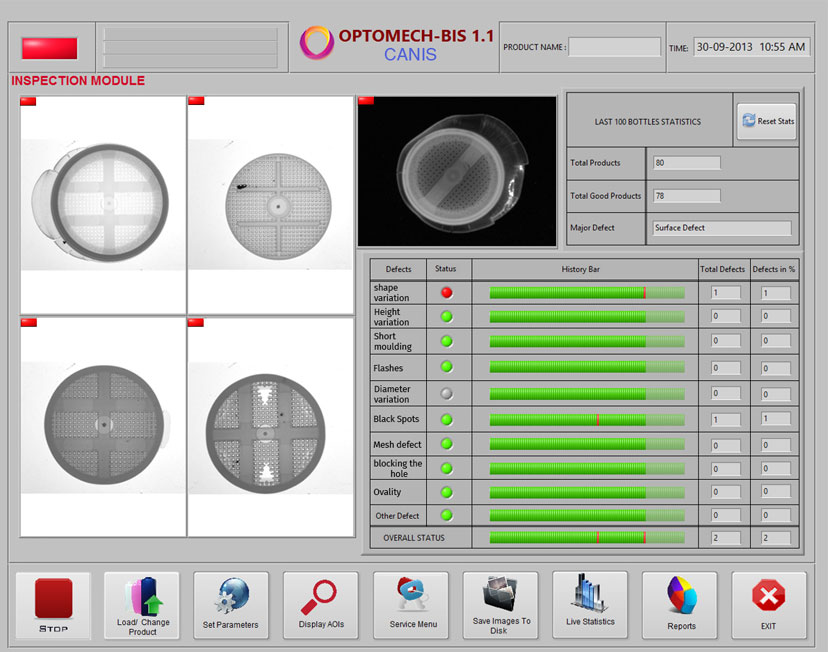

The user friendly software, allows the user to set the criteria and tolerances for rejection.

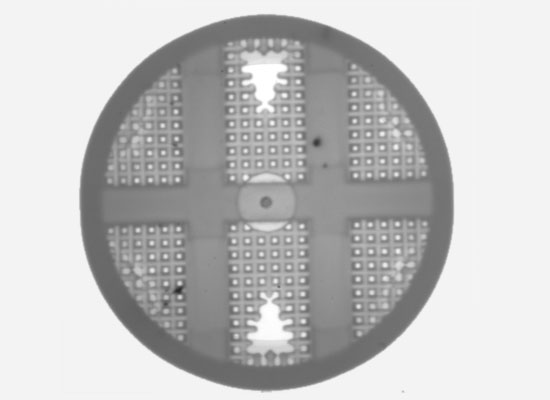

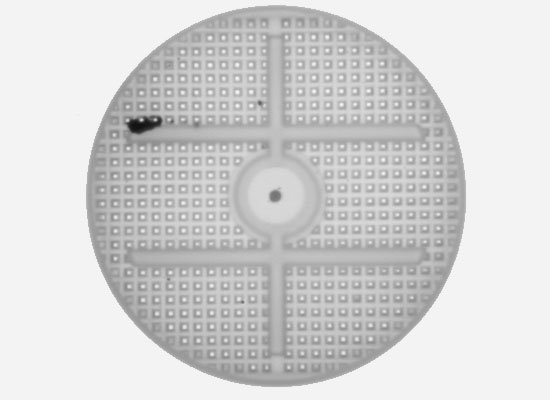

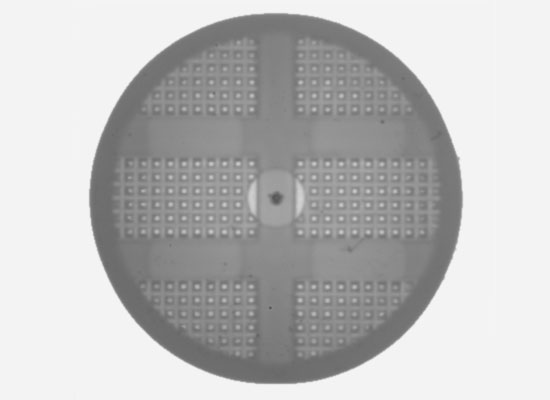

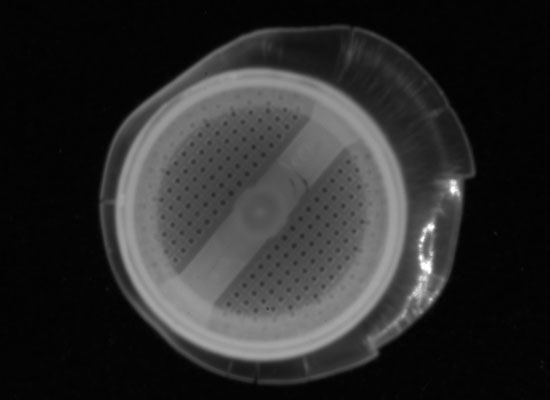

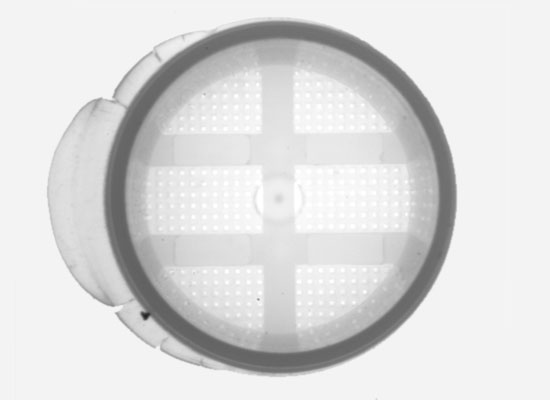

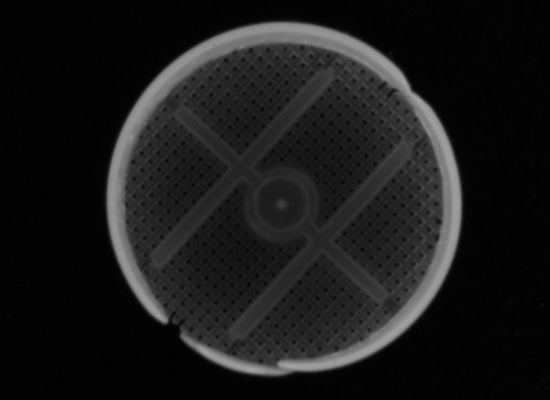

Inspection Images

Inspection Points

- Incomplete blowing or plastic part shape variation.

- Height variation.

- Short moulding.

- Flashes, extra material.

- Under/short moulding, Nicks, Dents.

- Ovality, Diameter variation’s.

- Black Spots on the outer surface.

- Mesh defect- Broken Mesh, Blocked Holes.

- Grease inside (blocking the hole).

- Large Hair inside the cap.

Learn more

Technical Specifications

| Model | Optomech – Desiccant Canister Inspection System |

| SPEED | Up to max 250-300 Caps/min. |

| Plastic part size | Height: 50 Min/ 200 mm max Width: 110 mm Max Depth/Dia: 95 mm Max |

| ACCURACY | 0.1 mm For plastic part height of 20 mm. |

| DEFECTS DETECTED | Flashes; Short molding; Diameter, Ovality variation Canister base: Mesh Defect, broken Mesh, blocked holes |

| MACHINE SIZE | Length: 1850mm Width:850mm Height:1670mm Weight: 150 Kg |

| MACHINE SIZE | Main conveyor: Belt Width : 60 mm Length: 1850mm Belt Speed: Upto 30 m/min |

| CONVEYOR | Electric: Voltage and Current: Ac 415 v 3 phase, 5A. Compressed Air : 6-10 Bar, oil free clean air, Push in connection 6mm. |

| OPERATING CONDITIONS | Temperature: +10 °C to +40°C Humidity: 40% -90% RH, non-condensing. Maximum operating altitude: 1900 m |

Machine Dimension